It all began in China.

We were given the challenge to develop innovative materials combined with cutting-edge fabrication for new applications through a new partnership between ‘ArtCenter College of Design’ (CA) and ‘Neuni’ (Shanghai). We also had to look for opportunities for material innovation through Neuni's network of manufacturers, digital fabrication & design studios throughout China.

Sponsored by

Neuni Material Design Studio, Shanghai

Field research trip

Real-world, three-week field study trips to over thirty-three companies in China and lectures from manufacturers throughout the term served as the driving forces for the design studio.

Key Takeaways :

-

Tradition

-

Craftsmanship

-

Mass manufacturing process and techniques

-

Working conditions

Factories that inspired me ….

Burgeree and Jollying Luggage Factory were a true inspiration to me on my research trip since they understood my luggage problem and worked on sustainable problem-solving.

In the end, I collaborated with them to construct my luggage as well.

Inspiration

I saw around thirty-three factories while travelling throughout China which gave me the idea for re:pack.

My broken suitcase, clothes that crumpled in the luggage, and the challenge of juggling three bags at once when travelling served as inspiration for me to design a better one.

I reasoned that many others might have experienced the same issues with their bags as I did.

As I was waiting for my aircraft at the airport, I started asking individuals about their travelogues and experiences.

Understanding users' experiences and relationships with their luggage

I felt that the airport was the best place to connect with my target user, who might be experiencing difficulties as they pack and travel, and understand their relationship and experiences with their luggage. I conducted user interviews at the same time as I was waiting at the airport during our program, as we were flying to visit factories in China.

Defining the Problem

On part of consumers

When traveling, bags are a crucial component. Travellers, however, do not feel personally connected to them. Furthermore, there isn't a mid-range luggage available that embodies the user's style and individuality.

It is common for travellers to need to have many bags for various uses

Quickly dents and becomes damaged when traveling

Poor shopping experience and the dull, uninspired luggage available

It's difficult to distinguish one's bags at the baggage carousel because they all seem alike.

Possess a subpar internal system of organization

On part of the aviation industry

Large volumes of food waste and plastic are burned or dumped in landfills. A few airlines are making an effort to address the issue, but it's challenging.

Plastic wrappers for snacks, cocktail straws, napkins, cans, and packaged juices—some of which were opened, maybe one cup filled, and then discarded—none of which were recycled. This is in addition to the flight's direct environmental impact.

Airlines produce

5.2 million tons

of waste every year which mostly consists of plastics, aluminum and tin cans and it all ends up into landfills and oceans.

By 2030, airlines are projected to produce 10 million tons of waste annually.

Challenge

What if we could make better use of the garbage that airlines discard, preventing it from ending up in landfills or the ocean, and improve the sustainability of the materials used to build luggage?

Creating a circular economy in which waste from the airline business is recycled into luggage for air travel, thereby cutting down on waste entering landfills and the ocean and lowering carbon footprints.

Creating a Circular Economy

Driving innovation

Not much has changed in terms of bag structure and design since the 19th century.

-

Just a few creative changes and improvisations in the materials utilized have made it lighter, more affordable, and more sophisticated to satisfy the pricey demands of the present.

-

Since then, the quality has declined as well.

-

These days, luggage can sustain damage easily and is no longer waterproof.

Design Criteria

How might we redesign mid-range luggage with a user-friendly design that embodies their personality, is well-organized, and is comfortable to carry?

Ideating features

Aspects of Luggage

Re:trace

(Up-cycled material)

Re:pack

(Luggage)

User Persona

Ideation 1

What if users can build their own customized luggage?

Failed Experimentation - 1

Material Testing

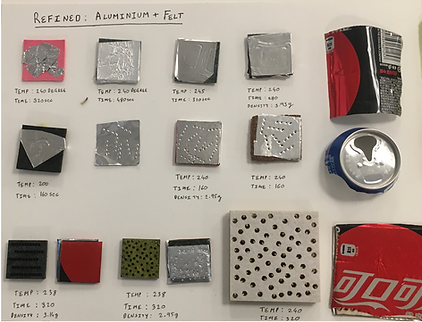

Initially, I experimented with various materials exhibiting the properties of being lightweight which would increase the structural density of the material, making it stronger, dustproof and waterproof. I tested them under various conditions and temperatures..

I experimented with….

-

R-PET felt fibers

-

PET plastic

-

Aluminium

-

Bioplastic to tes waterproofness

-

Mint to add aroma to the luggage's inside

-

Bubble wrap

Bioplastic didn’t help make the material waterproof and adding mint to R-felt didn’t give out a good smell instead it gave out a pungent bad smell.

Plastic directly from plastic bottles and raw felt fibers didn’t bond well together.

R- Aluminum bonded very well with R-PET Felt making the material extremely rigid and strong, making it the most successful experiment.

Bioplastic didn’t help make the material waterproof and adding mint to R-felt didn’t give out a good smell instead it gave out a pungent bad smell.

Design & Functionality

T

These designs and prototypes demonstrate the conception and testing stages of the project so that the user can design and construct their baggage according to their travel plans and arrange the items inside it any way they choose, instead of using the pre-made luggage

-

Creating personalized organized compartments for traveling.

-

Understanding Forms

-

Portable sizes of compartments

-

Attachment of modular compartments in luggage

-

Ways of keeping things organized and easily accessible.

Ideating on interior organizational structure and attachment of customized organizational segments onto the luggage and expandability of the exterior for easy storage.

Ideating on the attachment of different segments to create a modular personalized luggage

Testing and mapping out the space inside the luggage of how the clothes and things would fit in the customized organizational segments when placed together by tape drawing over the existing luggage

Ideating on interior organizational structure and attachment of customized organizational segments onto the luggage and expandability of the exterior for easy storage.

Key Learnings

Users thought the luggage was very organized, but they had trouble figuring out how to attach the organizational block to the luggage and were unable to estimate the size they would need for their trip.

They discovered that customizing their bags each time was confusing.

R- Aluminium bonded very well with R-PET Felt making the material extremely rigid and strong, making it the most successful experiment.

Personalized Modular Luggage

Ideation 2

What if the attachment was made as simple and portable as possible with just one modular component—a laptop bag—?

Failed Experimentation - 2

Material Testing

Several Iterations of material testing were done to make it as light and strong as carbon fiber.

By testing multiple cut patterns over felt, using external factors to test the strength and effectiveness of the material, the prototype shows features of developing the desired results after testing and the material under different temperatures and conditions.

Aluminum under 220 degree really helped bond with R-PET felt. However, the material was still heavy almost the same as the material used to make luggages.

Adding holes really helped make the material lighter but it was very minor.

Adding too many holes of different sizes really weakened the material and it was hard for aluminum to bond with the R-Felt under the tested temperature

Aluminum under 220 degree really helped bond with R-PET felt. However, the material was still heavy almost the same as the material used to make luggages.

Design & Functionality

Based on previous feedback, I began focussing on and testing a single modular aspect in the cabin luggage before moving on to designing a bigger luggage with more complex modular functionality.

I began to ideate, prototype and test on a single detachable component of a luggage such that the part of the luggage detaches and converts into a laptop bag / briefcase / backpack to fit the electronics and necessary documents so that it could be easily detached from the main luggage while traveling and can be easily used while working on the road or attending business meetings or meeting clients.

Ideating on different forms of modular brief case.

Testing out attachment in scaled version

The design of the brief case felt really bulky and not stylish. It attracted more of middle aged businessmen than youngsters for whom it was intended towards.

Ideating on different forms of modular brief case.

Key Learnings

The briefcase was suited to fit only 13inch laptop and not 15inch laptop due to which users weren’t much attracted towards it.

It felt a bit complicated to align the attachment rails to the briefcase whenever tried to slip the briefcase back in onto the luggage.

The briefcase’s design seemed incredibly hefty and unfashionable. It was meant for youthful people, but instead, it drew in a greater number of middle-aged executives.

Adding holes to the R-PET Felt helped make the material much lighter- almost as light as carbon fibre.

Final Outcome

Creating a modular, individualized, well-organized cabin bag that is incredibly lightweight and robust and features a detachable laptop bag to enable people to work conveniently on the fly without lugging around extra bags.

Re:trace - Final Material Sample

Inspiration for Graphics on the Luggage

The luggage's material's design and graphics were inspired by an artwork from the Bauhaus Art Movement.

+

=

The best results came from equally spacing out holes of the same size throughout the R-PET felt material. This allowed R-Aluminium to connect effectively, producing a material that is both incredibly strong and nearly as light as carbon fibre.

Customizable printed recycled tin can pattern on recycled aluminum from the airline industry

Density : 129.31g ( 28cm x 20cm)

Almost as light as carbon fibre yet recyclable

How is re:trace different and better ?

-

Sustainable /Recyclable

-

Extremely light weight than current materials used to make luggage.

-

Almost as light as carbon fibre.

-

Very sturdy and strong

-

Highly Impact Resistant

-

Eye catching and fashionable

Functional and Design

Expanding the briefcase's vertical dimension made it easier to accommodate computers, office supplies, and paperwork of various sizes. To make it easier to slide and remove the briefcase as needed, a single rail attachment was added.

Well Organized

You can effortlessly keep your clothing ironed and separate your new from old ones while you're out and around.

Modular Brief Case

Now you no longer have to carry a separate laptop bag. Keep all your documents, gadgets and passport easily accessible on the go.

Impact

Environmental

Creating a circular economy in which the waste from the airline industry is recycled into luggage for air travel, thereby cutting down on the amount of waste that ends up in landfills and the ocean.

Social

The brand fosters the development of a network of like-minded people who want to adopt sustainable travel habits and, in turn, inspire and motivate others to do the same.

Economical

The material developed may be produced at a lower cost for the mass market because it is essentially made by turning waste into treasure. This makes it very economical and feasible to manufacture. It is impact-resistant, lightweight, and durable in addition to protecting the environment.

Re:pack - Fresh out of the factory

(Soon launching on Kickstarter)